by Amélie ELKIK

Hundreds of offshore platforms are now reaching the end of their useful life and their number will increase significantly by 2040. As a result, a sector for the dismantling of oil and gas infrastructure is emerging as regulations are being forged. However, is the systematic use of decommissioning the best economic, societal and environmental option? Not so sure.

Let’s start with the numbers. According to the IHS Markit Offshore Decommissioning study published in November 2016, spending on offshore oil installation dismantling projects will increase from USD 2.4 billion in 2015 to USD 13 billion per year by 2040, an increase of 540%. The reason is simple: 3,000 platforms are arriving or will arrive at the end of their life by this deadline – in other words, the fields exploited will be empty.

It is therefore not surprising that dismantling is now becoming a major concern for the global oil and gas industry. In the North Sea in particular, where the installations are the most dated. But the Gulf of Mexico or the Black Sea are also affected. Not to mention a few scattered platforms off Indonesia and those that will later come from West Africa.

However, given its financial and temporal cost first, and in a long-term perspective marked by an intensification of tensions on metal resources in particular, is decommissioning the only option?

Reuse here too?

Conversion could – under certain conditions – be added to the choice of private companies or States in charge of ageing platforms.

The steel that makes up a large part of offshore installations is characterised by its very high quality, similar to that of aeronautics. The structures that have hosted more or less numerous personnel are secure and have been subject to regular maintenance during the operating period.

In many respects, therefore, and when they have been properly maintained by the operator, their strength is not in question.

However, the environmental issue is increasingly raised by NGOs or institutions. From this point of view, while the debate is not settled, several elements argue more in favour of maintaining and reusing some of the platforms than of their total dismantling.

First of all, it should be noted that since the slicks are supposed to be empty of oil or gas, the risk of oil pollution is ruled out. But the impact on marine life is worrying. While it was real when the sites were established and put into production, the majority of underwater structures have long since been repopulated by corals, fish and other ocean species. For example, “structures in the North Sea facilitate the presence of the mollusc Mytilus edulis, which modifies habitat to facilitate the presence of other organisms,” noted Australian researchers in the journal Science of the Total Environment (1). Certainly “habitats and ecological communities are now being modified from their pre-existing configurations,” they recall. But dismantling would not ensure a return to historical status because the new ecosystems “challenge conventional restoration“. Especially since “decommissioning options are likely to differ considerably in their effects on biodiversity, particularly between partial and complete removal options, the latter resulting in an almost complete loss of associated reef biota“.

Finally, it should be noted that, in terms of employment, the conversion of platforms could provide a local pool, even if it will in no way be comparable to the manna of professionals generated by the oil and gas industry.

Offshore platforms: a valuable “real estate” asset?

In all these respects, many solutions can therefore be devised to reconvert existing offshore installations by dismantling them only in part. Obviously this will depend on the geographical and economic environment.

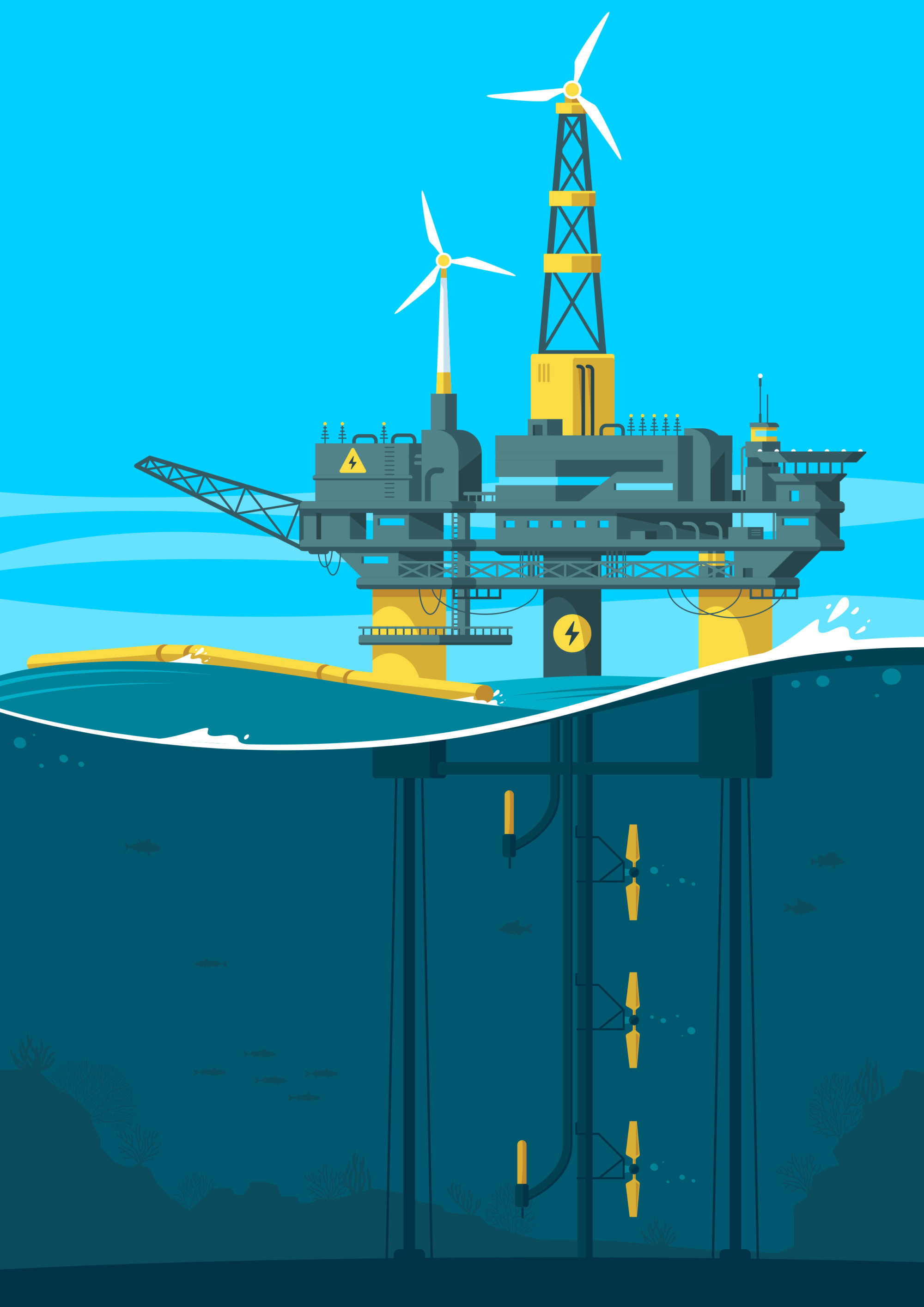

But at least 4 types of recovery are emerging. Industrial first. In the North Sea, former platforms could be used as a basis for the establishment of electricity substations to redistribute energy produced by offshore wind turbines to the continent. Others, as is already the case in Norway, could make it possible to install CO2 storage systems in hydrocarbon deposits that are now dry. And why not build desalination plants there. An untimely option in the North Sea but interesting in Africa, for example, where water stress is already a problem.

Off-loaded platforms could also accommodate commercial services. In near-shore areas, where maritime traffic is dense, some infrastructure could support congested port areas (e. g. off the Netherlands).

Another possible type of recovery is to use the emerged and submerged part of the structures for research. One could imagine building ocean monitoring and observation centres. Or for tourism by offering eco-tourism activities for example.

In any event, the conversion-revaluation option will require intermediaries to act as a link between an oil operator and the potential buyer. But the benefits should attract attention. For the reseller-operator, it is a saving of money first. It would thus not need to carry out its entire dismantling and could achieve a substantial saving of 15-20%. Out of amounts of up to several hundred million dollars, this is significant. Not to mention the time savings, when normally lifting operations (linked to the availability of lifting vessels and weather uncertainty) and ground handling operations weigh heavily on schedules.

For the buyer, it is a guarantee to have access to a kind of address at sea – any platform being placed and anchored in the ground – without having to work in a very complex marine environment and in which it is impossible to improvise. And here again, with the footprint acquired, the project planning can be shortened.

Exit door or entrance door, the reuse option is therefore attractive on paper. It remains to be seen how it will be implemented.

(1) « Decommissioning of offshore oil and gas structures – Environmental opportunities and challenges », par Brigitte Sommer, Ashley M. Fowler, Peter I. Macreadie, David A. Palandro, Azivy C. Aziz, David J. Booth. Publié le 12 décembre 2018. Editions Elsevier.